Waste, Recycling & Circularity

We put the “WAS” in waste.

It’s time to look at waste for what it is – a revenue stream in the trash.

Using data and strategic insights, we’ll keep your materials and money flowing back into your business by helping you reduce waste - or prevent it altogether through circular systems.

Whether you’d like to reduce waste within your products and packaging, operations, business model, or supply chain – we’re ready to help. We offer comprehensive services organized into two levels: LEVEL 1: Reduce Waste, Increase Recycling & Composting and LEVEL 2: Implement Circular Systems (Maximum Benefits). See what interests you!

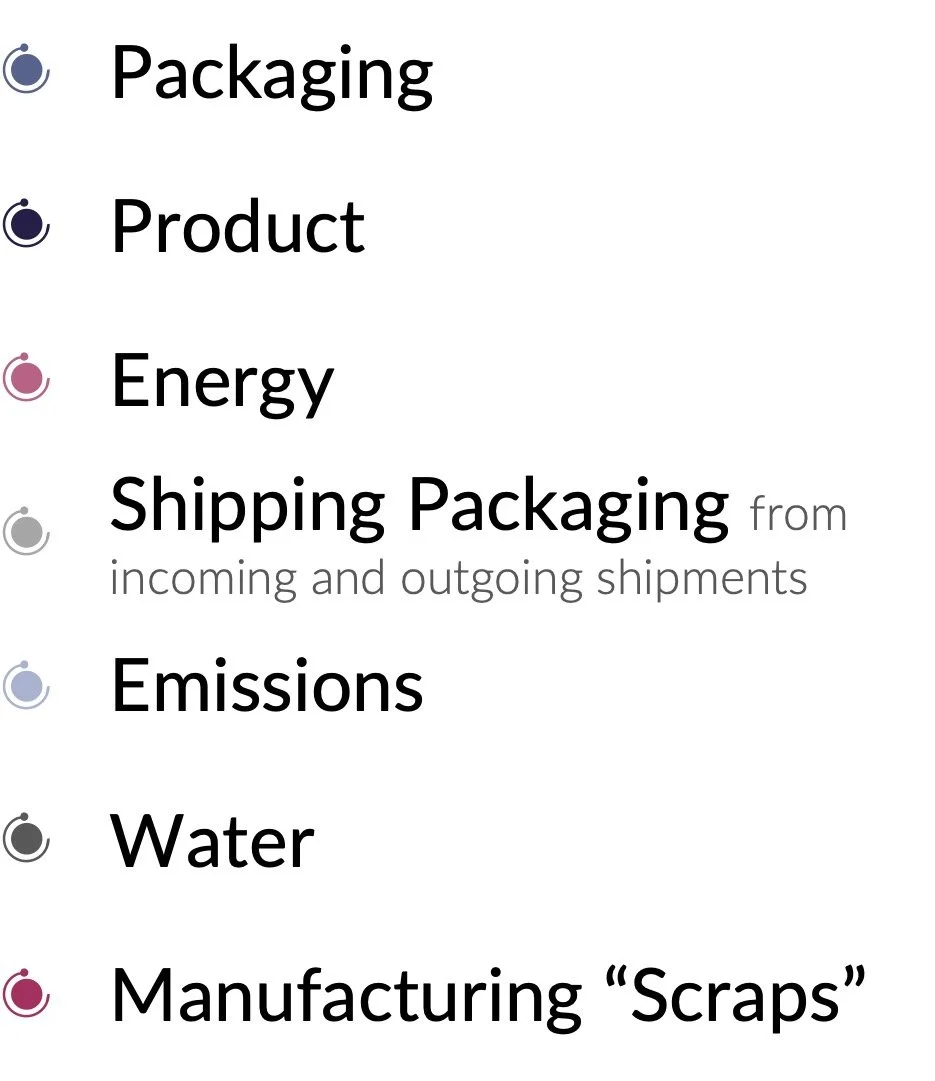

We can help you reduce all types of waste, including:

There are numerous, important benefits to waste reduction.

Consider us your collaborative partners in reducing waste, increasing recycling, and even incorporating “circularity” (or reuse) into your business.

It all starts with you deciding what you want.

LEVEL 1: Reduce Waste, Increase Recycling & Composting

Choose one action or many! We’re also happy to discuss projects not listed below.

-

We can help identify how your products and/or packaging can use fewer resources and increase their chances of being recycled or composted at their end of life.

• Lightweighting: We’ll help you identify which of your products and packaging can be adjusted to use less material while still meeting regulatory requirements.

• Design for Recycling or Composting: Though we’re not product or packaging designers, we are experts in data analytics and scenario modeling and can provide your design team with essential information to help products and packaging stay out of the landfill. For example, we can do a thorough assessment of what is currently happening to your products and packaging at their end of life around the world and assess how that would change based on design and material changes. We can also help you determine the most effective messaging to put on your products and packaging so they’re most likely to end up in the recycling bin or at a compost facility.

• From Virgin to Recycled Material: Lean on us to develop systems that can help you track your progress in moving from using virgin material to post-consumer or pre-consumer recycled material in your products and packaging.

-

We can help you streamline your processes to be more efficient and waste less.

• Increase Operational Efficiencies: We’ll identify waste “hot spots” within your operations, see which solutions work best via our data models, and facilitate implementing changes to reduce waste and increase recycling and composting. See Our Process section below for more details.

-

We can help you reduce emissions by switching to using more recycled and bio-based materials and reduce the overall waste your facilities receive from supplier shipments.

• Sustainable Sourcing: There are pressures for companies to source more recycled and bio-based materials in place of virgin materials, and doing so could help lower your company’s Scope 3 Category 1 emissions. We can dive into your procurement data to identify which materials can be replaced, estimate the potential emission reductions you’d earn by doing so, even work directly with your suppliers if you’d like.

• Waste from Shipments Received: We can support or lead supplier engagement efforts to reduce the incoming waste you receive from procurement shipments - reducing your waste disposal costs and employee time managing the waste.

LEVEL 2: Implement Circular Systems (Maximum Benefits)

What is circularity?

Circularity is the concept of reusing products and materials in their same form for as long as possible, with the goal of eliminating waste and pollution. What does that mean for your business? It is not about making your systems more efficient – it is about reimagining your systems from the ground up to focus on reusing materials and designing out waste.

For example, instead of your products and/or packaging becoming waste once used by the customer – imagine if they were returned to you so you could reuse the materials. Could you refurbish, remanufacture, or wash and resell the items? Every business has its own challenges and opportunities – and we can help you evaluate if you can systematically recover the value of your materials across your company in an endless loop. We’ll aim to keep your materials and money out of the landfill and flowing back into your business.

Have ambitious reduction targets? We can help.

Implementing circularity measures are the quickest way to achieve dramatic material/emission reductions and reach sustainability goals such as:

Single-Use Plastic Reductions

Net Zero Emissions

Zero Waste to Landfill

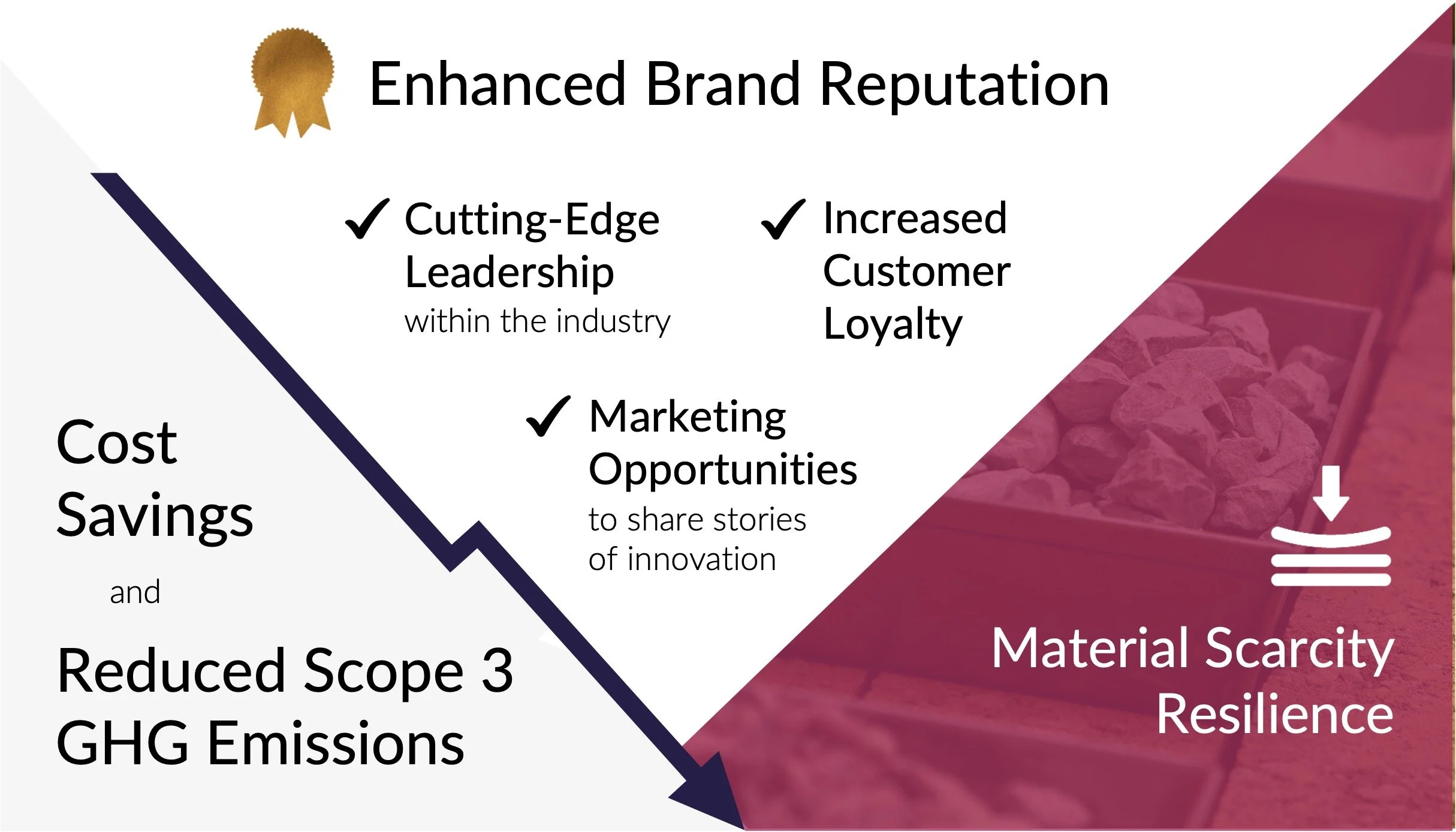

Other benefits of implementing circular systems aside from cost savings include cutting-edge leadership within the industry, compelling stories of sustainability innovations for marketing, earning customer loyalty, etc.

Risks are increasing:

Materials are becoming more scarce

Procurement costs are increasing

Global supply chains are becoming more vulnerable to disruption

Expectations are rising across industries for companies to become more sustainable

When discussing the risks business face in modern times, father of the circular economy Dr. Walter R. Stahel once said, “The biggest risk is often NOT to change.”

Our suite of circularity services are organized across the categories of products and packaging, operations and business model, supply chain, and circularity strategy. Choose one action item or many! We’re also happy to discuss projects not listed below.

-

We can help you redesign your products and packaging to use significantly fewer resources and be reused at the end of life.

• Use Circular Infrastructure: To recover the most value from your products and/or packaging, have them participate in a system so that they are returned to you when the customer is done. We can identify if an existing circular infrastructure (like Loop and Trove) will work for your business needs, and if not, help innovate new infrastructure that will. We will also explore the infrastructure to wash, refurbish, repair, etc. available for your specific products and packaging in the locations of your operations and customers to prepare them for a second life.

• Design for Circularity: Items destined for a long life of reuse will need to meet certain durability standards. We can help identify key design elements needed for your products and packaging to effectively “close the loop” and live multiple lives. For products and packaging that don’t retain much value after the first sale and make reuse impractical, we can help problem solve what adjustments should be made to the items so they are more likely to be recycled or composted at end of life. We can also determine how to reduce waste and emissions from upstream processes (and in the product and packaging itself) in the absence of reuse downstream.

-

Together, we can reimagine your internal and external processes to maximize the value of the materials that flow through them.

• Circular Operations: We begin by identifying the waste hot spots in your operations (manufacturing, construction, transportation, etc.) Then, we explore reuse solutions material to your business. This can include altering or even redesigning manufacturing processes to dramatically reduce your scrap rate and other waste. We can help you extend the lifespan of existing equipment and enjoy long-term savings by identifying when to repair instead of replace units when future problems arise. If you have shipments between facilities, we can help you implement reusable transport packaging to significantly cut waste and costs – and better monitor product quality and flows while on the road. The list goes on. Have unavoidable wasted material? We’ll explore if it could be used by your operations at other sites, if the supplier would like to buy it back, or try to find a buyer in the marketplace using platforms like Rheaply and other methods.

• Zero Waste to Landfill: The quickest way to reach Zero Waste to Landfill is by preventing waste in the first place. Next, reduce waste where possible and reuse the rest. Recycle and compost as needed. Let our team guide the way.

• Net Zero Emissions: Have Net Zero Emissions (Scope 3) commitments? Implementing circularity measures should certainly be on your decarbonization roadmap.

• Circular Business Model: Revolutionize your business (and industry!) by moving to a circular business model. These often include business models that involve:

o Leasing or renting products to customers

o Offering packaging reuse subscription services (like Loop)

o The resale or re-commerce of your products

o Offering bulk refill stations

o 3D printing of parts for repairs

o Battery recycling and remanufacturing

o Creative recycling processes ex. Zymergen microbes to break down and repurpose plastics

o Using material that is easily recycled, like glass and metal, or composted (Though recycling is not technically “circular” since the value of the material is downgraded, it can still provide significant environmental benefits depending on the case)

The list goes on! We’ll use data analytics, creative problem solving, and your business goals to develop innovative circular business model ideas to transform your unique company.

-

Did you know a supplier may become a well-paying customer when you effectively implement circularity measures in your business? We can help you explore that option, and some other important things, too.

• Sustainable Sourcing: There are many pressures for companies to source more recycled and bio-based materials in place of virgin materials, and doing so could lower your company’s Scope 3 Category 1 emissions. We can dive into your procurement data to identify which materials can be replaced, estimate the potential emission reductions you’d earn by doing so, even work directly with your suppliers if you’d like.

• Waste from Shipments Received: We’d love to help you and your suppliers implement reusable transport packaging to dramatically cut the single-use plastic packaging waste you receive and pay to discard (such as plastic film, pallets, air bags, straps, etc.). Reusable transport packaging is of higher quality and can benefit the products shipped. For example, reusable pallets have embedded technology to track location, temperature, distance traveled, and more – ensuring the products you purchase arrive on time, are not compromised due to temperature, etc. We can also help roll out reusable transport packaging in shipments between your own facilities for you to enjoy maximum benefits.

• Build Circular Partnerships with Suppliers: If your company can’t reuse its waste, perhaps the original manufacturer of the wasted material can. Selling materials back to their manufacturers (in the form of a sale or rebate on your next purchase) can pay off significantly. We can help identify these opportunities, prepare data for discussions with suppliers, and determine an appropriate price range to negotiate.

The Process (LEVELS 1 & 2)

We’ll adapt our proven process to your project to bring lasting, sustainable change.

1. Waste Health Check - We Quantify the Problems

First, you share with us the scope of the project you envision based on the services described in Level 1 and Level 2 above. Then, we’ll take a deep dive into the situation to identify areas for improvement. Using advanced data analysis and in-depth conversations with employees and stakeholders, we’ll locate waste hotspots and inefficiencies within the systems and share the results with you. We will make recommendations on where to focus based on the results of the health check.

2. You Decide Where to Focus

You review the Waste Health Check results and recommendations and decide on the primary problem areas you would like us to improve. Then, we will meet with you and your team to ensure we understand your vision and the path forward.

3. We Find & Model Solutions

First, we’ll benchmark how other companies have solved similar problems to avoid recreating the wheel, if possible. Then, we’ll work with your team and stakeholders to brainstorm solutions. This is an important step, as they have essential institutional knowledge and can provide valuable insights into the feasibility of different ideas. We will model a variety of solution scenarios to determine their benefits and identify which are most strategic for your situation, using cutting-edge impact modeling tools such as:

Life Cycle Assessments (LCAs)

Our customized Predictive Modeling Tools

Detailed data analyses

4. You Decide the Solutions to Implement

We report the results of the solution data modeling, learn which ones you like best, and develop implementation plans. We will create business-case documentation to:

Demonstrate how the top performing solutions will reduce waste

Provide detailed cost analyses

Estimate cost benefits and ROIs

5. We Facilitate Implementation (If Needed)

If you’d like, we can guide your team through the process of implementing the changes, taking care to cause as little disruption as possible. We can also develop an Implementation Tracking Tool to track the rollout of the improvements.

6. We Train Your Staff (If Needed)

A new system is only effective if it is followed correctly. We can support or lead the training of your staff in using the new system(s) and making it part of the daily routine. Once your staff is trained and the system(s) is up and running, you’ll begin experiencing the benefits.